If you came here by way of my

Electrical stuff

menu, you will have seen a

photograph of the front cover of "Model Making For Young Physicists" by

A.D.Bulman (John Murray, 1963). That front cover featured a drawing of the

project about to be described here.

It's a very simple project, but it needs to be well-made if it is to perform

satisfactorily, because it generates very little power - and every milliwatt

is precious.

(Now, why do those last four words remind me of Monty Python??)

If it's made without attention to detail, it probably won't work at all.

On the other hand, if it is made carefully, it can be a source of

great fascination. Simple it may be; but it's possible to do quite a lot of

very interesting physics with it. (I'd like to think that science teachers

may find it a source of inspiration.)

My own model started out pretty much as Bulman described it, and worked

reasonably well for a while. Over time, however, the second law of

thermodynamics took its toll: parts wore out or went rusty. Eventually the

electromagnet was removed and used for something else, with the remaining

bits tied together with a piece of wire, stored away and forgotten about.

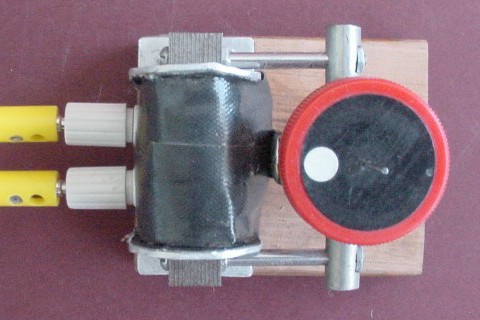

In 2002, I found it and decided that it would be fun to get it going again.

After a few hours of re-building, fiddling and adjusting, I came up with a

pretty neat little gadget. Here it is:

The spindle consists of a large sewing needle with the eye cut off. Onto

this is fixed a cross made from twelve small plates cut from thin sheet

iron, each 25mm x 6mm (1" x 0.25"). Each of these plates has a small central

hole, just big enough for the needle to pass through. The plates are stacked

up as laminations so that they run alternately "north-south" and

"east-west".

The iron sheet we (my Dad and I) used for the laminations was taken from a

spool which at some stage had probably held a length of wire. The outside of

this spool was painted pale blue with red markings (as can be seen from the

picture above). This layer of paint probably helps (if only slightly) the

performance of the model, as it provides a layer of insulation between the

plates and thus helps to minimize eddy currents which could have a dampening

effect.

I'm not quite sure how my Dad fixed the cross to the needle. He probably

followed Bulman's instructions fairly closely, the cross being wired in

place while being soldered, in the hope that enough solder would hold the

strips in place on the needle. Or perhaps he just glued it together with

epoxy glue - I'm not sure. Whatever he did, it was a neat and effective job;

and the whole assembly has stood the test of time extremely well!

In this next photograph, you can see the construction of the cross quite

clearly.

You can also see the upper support, which is attached to the base under the

electromagnet by a couple of nuts, bolts and washers. This is bent up at

right-angles to rise between the rotor and the electromagnet; finally,

another right-angle bend completes the zigzag, and the rotor is supported by

a hole drilled in the top horizontal section.

Actually, when I revamped the model, I reinforced this upper support by

attaching another short piece of brass strip as a strut to produce a

triangle, as shown here:

This adds considerably to the overall robustness of the model.

You can also see a smaller brass strip, bent into a serpentine curve with a

small hole drilled at one end to lend support to the lower end of the rotor.

The strip is attached to the base by a single bolt through a larger hole at

its other end (more about this shortly).

In Bulman's original model, there was no lower support strip. His model

relied on the upper support and a strip of brass with a small indentation to

support the needle at its point.

(Also, his upper support was attached near the edge of the base, where our

lower support was attached).

The original flywheel was made from a disc of hardboard 0.6cm (0.25") thick

and 3.2cm (1.25") in diameter. The needle was passed through a small central

hole, and the disc glued in place. Like the cross, this has lasted well

also.

The flywheel was painted white, with a red circular dot painted near the

edge above one of the cross-arms. (The reason for this will be explained

shortly.) When I revamped the model in 2002, I added a 4cm diameter red

plastic bottle cap with a central hole, which fits quite snugly over the

hardboard disc, and placed on it a 3.2cm white circular sticker which I had

coloured black with a marker pen. I then placed a smaller (8mm diameter)

white circular sticker on the black one, near to the edge, and again above

one of the cross-arms. Part of the reason for doing all this was that the

old flywheel was a bit tatty, and I decided that the whole thing could do

with a face-lift. It turns out that the extra mass also provides a stronger

flywheel effect (i.e. more angular momentum), which I think is probably a

good thing.

In the original model, made following Bulman's instructions fairly closely,

the point of the needle rested on a strip of brass of the same type as the

supports, attached to the base by a couple of small screws. A small

indentation was made in this brass strip for the needle point to rest in.

The problem with this was that, over time, the spinning needle drilled

itself deeper into the soft brass strip until it actually became a rather

tight fit, completely defeating the strip's purpose. One could always replace

it; but it occurred to me that it was possible to do a lot better.

There used to be a glazier's shop in my home city; sadly, this became just

another victim of economic rationalism and globalization a few years ago.

On occasion, I'd buy various little things from them for various projects.

One such project (I won't go into detail) required small glass discs. It

turned out that, from time to time, the glazier found it necessary to bore

holes in sheets of glass to meet some customer's special needs. They put

the resulting discs aside and eventually threw them out.

Ever on the lookout for useful bits and pieces, I asked if I could have some

of these little discs. Sure enough, they gave me quite a lot!

One of these discs found its way into this project. Using a glass drill, I

made a small conical depression in one side. I placed a circular sticker on

the other side, and glued it to the base with ordinary wood/paper glue so

that, with the needle vertical, its point would rest in the depression.

I mentioned earlier that I'd have something more to say about the lower

support for the rotor.

Theoretically, the lower support is not necessary. (This was obviously

Bulman's point of view, too.) If the needle point is sitting in the conical

depression in the glass disc, and the rotor is supported above the cross,

why would it need any other support?

The reason is that the rotor is started spinning by a quick twist with thumb

and forefinger

("Here comes the twister"

Once the rotor is spinning, however, the lower support becomes redundant.

Therefore, it's highly desirable that the needle should not touch the sides

of the hole once it is released, so as to reduce overall frictional losses.

By attaching the lower support to the base firmly, but at a single point,

it's quite easy to adjust things so that this requirement is met.

Now: to the electromagnet.

An old soldering iron I'd had since the early 1970's eventually wore out to

the point where it was no longer a going concern. At some stage in the early

1990's, I pensioned it off and bought a modern temperature-controlled

Dick Smith solder station.

I don't throw old things out. (My wife calls me a "hoarder".) So I still had

the beat-up old soldering iron lying around in 2002, when I decided to

rescue the synchronous wheel.

The soldering iron had its own transformer, which I dismantled as carefully

as possible. A hacksaw was needed to cut through the laminations - a

somewhat hair-raising job, if one is to avoid damaging the windings. This

successfully accomplished, I unwound the wire. I used half of the primary

winding to make the electromagnet for this project, and eventually used the

other half for the next project described in this website (the

single-solenoid electric engine

). The thick, short secondary I put aside. (It may see service as the

primary of a Tesla coil at some later stage.)

I don't know exactly how many turns there are on my electromagnet. Bulman

suggests winding on from 300 to 600 turns.

I used a section of the laminated core of the now defunct tranformer as the

core for my new eletromagnet. I prepared two ends from a piece of aluminium

sheet, and placed them on the laminations. I covered that part of the

laminations between the ends, and the insides of the aluminium ends

themselves, with gaffer tape, and wound the wire on, finishing the work with

a covering of more gaffer tape over the windings.

The piece of transformer core I used already had holes drilled in its ends;

bolts had passed through these in the original transformer, to hold it

together. I passed long steel bolts through these holes, added a nut to each

to anchor the bolts firmly to the core, and then placed pieces of

chrome-plated brass tubing liberated from an old telescopic TV antenna over

the bolts for most of their length.

I had a couple of large-diameter bolts left over from an earlier project.

The first couple of centimetres of these bolts, next to the heads, was

unthreaded. I cut the heads off, and also cut the threaded sections off,

leaving two short rods each tapered at one end. I used a file to make flat

areas on each of these near the untapered ends, and drilled holes to

accommodate the long bolts. Finally I used nuts to secure these rods onto

the long bolts to give the structure you can see in the photographs.

I used pieces cut from small right-angle shelving brackets bolted to the

aluminium end-pieces as supports for the white banana socket terminals, to

which I then connected the ends of the winding. Finally, I added some more

gaffer tape to give a tidy finish to the lower part of the structure, and

attached the whole thing to the base with four screws, two at each end.

I've gone into considerable detail regarding the constuction of this

project. Why?

Well, basically because I feel that if you only build one of the little

mechanical models described in this website, this one has the most to offer

from a scientific point of view. If you do decide to build your own

synchronous wheel, I'd like to try to ensure (as far as possible) that it

works well, so that you may have as enjoyable and educational an experience

from its use as I've had from mine.

It's necessary to have a source of AC power to operate the synchronous

wheel. Mine runs very nicely from

my old power supply

. Because of the need for AC, the bridge rectifier is not used.

If you have access to an AC power supply, you're in business. If you don't

have one, you can probably obtain a suitable plug-pack with an AC output.

With my power supply set to its 14V output, the model draws about half an

amp (which means that it's then running at about 7 watts).

All set?

So, you switch on, give the rotor a twist, and away it goes! Right?

Not quite. You need to spin it at just the right speed, with very little

room for error. However, if you do, it will indeed keep on spinning!

So what is the right speed?

This has to do with the frequency of the AC supply in your area. In

Australia, where I live, and in some other countries including the UK, the

frequency is 50Hz (i.e. 50 cycles per second). In the US and other

countries, the frequency is 60Hz.

In each cycle (1/50 or 1/60 of a second, depending on where you live),

current flows in the coil first in one direction and then the other, in a

smoothly-varying sinusoidal fashion. As a result, a

sinusoidally-varying magnetic field (denoted by B, and measured in

teslas) is generated between the poles of the elecromagnet, first in

one direction (north-south) and then in the other (south-north).

The critical point here is that a strong magnetic field occurs twice

within each cycle: one-quarter of the way through the cycle, and

three-quarters of the way through it, as indicated in the diagram above. The

fact that the field's direction reverses every time is immaterial for our

purposes; the cross laminations are made up from un-magnetized soft iron,

which will happily line up with a magnetic field oriented in either

direction.

Thus a magnetic field capable of lining up a set of cross laminations in any

one of four rotor orientations, 90 degrees apart, occurs 100 (or 120) times

each second.

Now, the cross has four arms, each of which passes each of the two poles of

the electromagnet on each revolution. If the rotor is spinning so that the

arms of the cross are close to the electromagnet poles each time the field

strength is at a maximum, and are as far away as they can be (i.e. at a

45-degree angle to the direction of the magnetic field) when when the field

strength drops to zero, it must be spinning at one-half of a turn per AC

cycle. This means that it will be spinning at 25 revs/sec (or 30 revs/sec).

Hence, under these conditions, the speed of rotation, in revs/sec, is

exactly half the frequency of the AC supply, in Hz (cycles per second).

Whenever the rotor is spinning, there are forces (friction with the upper

bearing and the glass disc, air resistance) tending to slow it down. If it

is spinning as just described, the repeated pull of the magnet on the cross

laminations as they approach the poles will give the rotor just enough

angular acceleration to overcome these losses, and thus take it safely

through its next quarter-turn. This condition, in which the rotor is always

"playing catch-up" with the AC power supply, produces synchronization and

hence constant-speed rotation.

So: how do you get the rotor spinning at just the right speed, so that it

will "lock in" and continue to spin at that speed? And how will you know

when you've got it right?

Simply spinning it at a somewhat greater speed, and waiting for it to slow

down to the correct speed and settle there, rarely if ever works. It will

just slow down through that particular speed, and ultimately stop -

unless you're very lucky (it's happened for me just twice).

It requires practice and a deft touch to spin it just right. It's not easy

at first, as you are guessing how fast to spin it, trying to acquire the

technique, learning from experience - and you may ask yourself:

"How do I work this?"

Believe me - you will know when you've spun it at just the right speed.

Within a fraction of a second, you will be aware that the little machine is

settling into a rhythm.

You may happen to spin it so close to the required speed that it just sits

there and continues to spin quietly as though it were the most natural thing

in the world. You will experience a deep feeling of inner peace.

If you've spun at it just the merest fraction slower or faster than its

required speed, you will become aware of a soft, slow throbbing sound

("whirr-whirr-whirr") as it alternately spins slightly faster and slightly

slower, gradually - over several seconds - settling down until everything is

in equilibrium. Then all you will hear will be the quiet, jiggly little

noise of the spinning needle as it lightly interacts with its bearings, and

the sound of your own breath as you slowly exhale in a sigh of satisfaction.

Spiritual stuff!

Of course, having done it once, and got the "feel" of how to do it, the

learning curve rapidly becomes easier.

Same as it ever was...

Is there any way to simplify this learning experience? Indeed there is - and

this is where the dot on the flywheel comes into its own.

Assume for the moment that the rotor is already spinning as described above,

at half the AC frequency. Suppose also that ambient light is at a fairly low

level, and that a fluorescent light is used to illuminate the model. What

will you see?

No doubt you are aware that the light from a fluorescent tube is not steady,

but flickers. (It can get quite annoying after a while.) How fast does it

flicker?

A moment's thought will convince you that it flickers at double the mains

frequency - for exactly the same reason that the magnetic field strength of

the synchronous wheel's electromagnet achieves its maximum strength at

double the mains frequency.

Now, since the flywheel makes one complete revolution over two complete AC

cycles, and since the light from the fluorescent tube is at its brightest

four times within those two cycles, it follows that the flywheel is

illuminated brightly four times during those two cycles.

Thus you will see the white dot illuminated brightly four times within one

revolution of the flywheel. This means that you seem to see four whitish

areas, apparently stationary, spaced at 90 degree intervals around the

flywheel.

You won't see four sharply-defined circular white dots, as shown in the

left-hand diagram below; but rather a ring composed of varying shades of

grey, with four quite bright patches and four rather dark patches within it,

somewhat like the diagram at the right.

In fact, even that is not quite correct. You will actually see something

like the right-hand diagram above - but rotated a bit. If the flywheel is

spinning clockwise, it will appear rotated slightly anticlockwise, as in the

left-hand diagram below. Conversely, if it is spinning anticlockwise, it

will appear with a slight clockwise twist, as in the right-hand diagram

below.

Why does this happen? As John Lennon once said, "You might well arsk". We'll

deal with the phenomenon in the next page.

If you've made a synchronous wheel of your own following these notes, and

had a bit of a play with it, you may be interested in further activities

involving it. If so, click on this link:

Mad Teddy's synchronous wheel, page 2

My home page

Preliminaries (Copyright, Safety)

My synchronous wheel (ca. 1967)

Ignore the stack of coins peeping out above the flywheel - they're just

propping the model up, as I had it standing on end while I took the picture!

).

No matter how carefully this is done, it is very difficult

to avoid a certain jerkiness in the action, so that the needle point will

quite likely not come to rest in the small depression. (It may even be

damaged during the process, if too much vigour is used.) So the lower

support is invaluable for keeping everything more or less in place during

this operation.

).

No matter how carefully this is done, it is very difficult

to avoid a certain jerkiness in the action, so that the needle point will

quite likely not come to rest in the small depression. (It may even be

damaged during the process, if too much vigour is used.) So the lower

support is invaluable for keeping everything more or less in place during

this operation.

Return to Electromechanical models sub-menu

Return to Electromechanical models sub-menu