Two of the three books mentioned in the lead-up to this page, "Model Making

for Young Physicists" by A.D.Bulman and "The Boy Electrician" by Alfred P.

Morgan, each presented a model which could be described as a "solenoid

engine". The most obvious difference between them is that one of them

(Bulman's) had only one solenoid, while Morgan's had two. The most obvious

thing that they had in common is that they both relied on moving

contacts.

Having built my

two-pole electric motor

, and thus knowing the hassles moving contacts can cause, I decided in 2002

to build a solenoid engine built on very different principles.

The fact is, my Dad and I did build a single-solenoid engine in the late

1960's, based somewhat along the lines of Bulman's model, using an old

solenoid my Dad had lying around (goodness only knows where he got it from,

or what its original function was!). The model did work, although not very

well; eventually it was dismantled, and some of the parts found other uses.

As you've probably guessed, the moving contacts were the main cause of its

ultimate demise.

Reduced to its bare essentials, a solenoid engine of the moving-contact type

can be represented as in the following diagram:

At the right is the solenoid - a coil of wire wound on a tube of

suitable non-ferrous material with a movable soft-iron core. This is

attached to a crankshaft (at left) which bears a slip-ring and a cam, both

made from some suitable metal (eg. brass) and electrically connected

together.

Here is a view from above:

Two brushes made from some springy metal are attached to the base so that

one is in permanent contact with the slip-ring, and the other is in contact

with the cam for exactly half the time when the engine is in operation. In

the above diagram, the relationship of the cam to the crankshaft is such

that the solenoid will pull only when the crank is above the level of

the bearings. In this configuration, the pull of the solenoid on the

armature - and hence the crank - will cause clockwise rotation of the

crankshaft, together with the slip-ring, cam and flywheel. Once the crank

has been pulled to the right-hand horizontal position, the cam is no longer

in contact with its brush and the solenoid is switched off. The flywheel

causes the crankshaft to continue to rotate (or "free-wheel") clockwise

until the crank is horizontal again, but this time over to the left. While

this is happening, the armature pulls the moving core part-way out of the

coil. Then the cam and brush will again come into contact, switching the

solenoid on so that once again it pulls - and the cycle continues until the

power is switched off.

If the cam were mounted at 180 degrees to the position shown here, the

solenoid would pull only when the crank was below the level of the

bearings, and the rotation would be anticlockwise instead.

The model my Dad and I built was pretty much along the lines of the diagrams

above. There may have been minor differences: the slip-ring and the cam may

have been at interchanged positions on the axle; we may have used a second

slip-ring with a semi-cylindrical piece of metal instead of an actual cam -

small details like that - I really can't remember; but the basic idea was

the same. (We probably tried various modifications at different times in an

attempt to improve the performance of the thing!)

It is possible to build a model which has a different geometry, but

essentially the same basic structure. The model described above looks

rather like an old-fashioned horizontal steam-engine. On the other hand,

another experimenter

(see his own

website

) has built an electric engine model which is more reminiscent of a Texan

oil pump! The movie of this is well worth a look - you can see the action of

the cam very clearly.

(While you're there, check out the movie of his Atkinson engine - nothing to

do with the present topic, but fascinating in its own right. Lots of other

interesting things there too - spend a bit of time having a poke around.)

In 2002, it occurred to me that it should be possible to build a machine of

this basic type without moving contacts, using opto-electronic

components to control the switching. Light-Emitting Diodes (LED's) have been

around for decades; so also have Light-Dependent Resistors (LDR's). Both are

reasonably cheap and can be obtained from electronics shops.

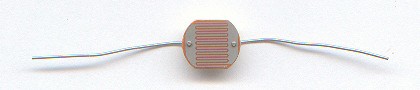

An LDR is a thin slice of cadmium sulphide (CdS), a light-sensitive

substance, mounted on a small piece of insulating material and with two

interleaved metal grids attached to the top surface. When light falls on the

LDR, the resistance between the grids drops dramatically.

This LDR is about 1cm across. In darkness, its resistance is about 45

kilohms (probably more in pitch-dark conditions); with a bright white LED

shining on it at close range, the resistance drops to about 80 ohms.

In the 1960's, when the tremolo effect was popular with electric guitarists

(remember Hank B. Marvin's style in some tunes by the Shadows, or

"Crimson and Clover"

by Tommy James and the Shondells?), technically-minded "musos" who owned

a "basic" guitar amplifier would sometimes add this effect by building an

oscillator circuit capable of flashing a small torch globe (this was

before LED's were common or cheap). The globe would be organized to shine

on an LDR which was wired into the amplifier's gain control, thus

producing the characteristic pulsating effect.

These days, of course, you can buy things like "opto-transistors" which do

essentially the same job as an LDR wired into a gain-control circuit, but

with everything built into a single integrated-circuit package and made from

more recently-developed materials with faster response times.

(By the way: I recently visited a museum which had a display of old-style

pigments used for making paints. Powdered cadmium sulphide is - or was -

used to make bright yellow paint! So I wonder if my use of a yellow LED to

shine on the LDR was an inspired guess - or whether a different

colour would have actually been better? Something to look into at some

stage...)

A circuit including an LDR can be used to control an electric engine. All

that is needed is some method of automatically controlling when a beam of

light from a LED falls on the LDR, connected so as to switch the solenoid on

and off at the appropriate times. What can be used for such a purpose?

From time to time, for other projects (unrelated to those in these pages), I

do a bit of resin casting with clear epoxy-resin. Of course, one always

makes up a bit more than is actually needed, to make sure that there is in

fact enough for the job in hand. Thus there will be a small amount left over

afterwards. Rather than throwing the excess away, I pour it into some small

container - a cap from an old spray-can, for example - and leave it to set,

on the very sound principle that "you never know when it might come in

handy".

Well, a clear plastic disc made in this way did come in handy - just

the job for the light-shutter in my single-solenoid engine!

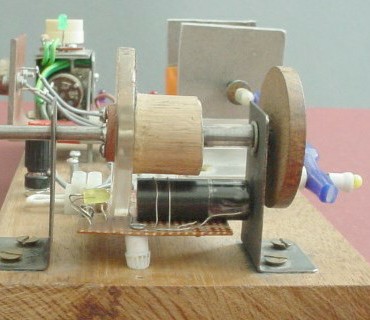

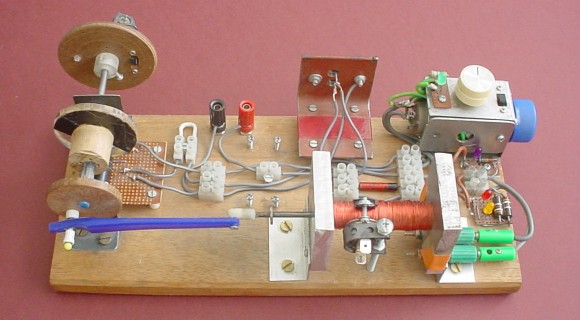

In the left-hand picture above you can see the clear resin disc, with about

half its area covered with black insulating tape. The right-hand picture

shows how a yellow LED is mounted to one side of the disc so that it can

shine into a black tube on the other side, provided the black tape is

not in the way. An LDR, of the same type as that shown above, is mounted

inside the tube, at the far end.

The LED shines all the time while the engine is running. Thus, for about

half the time when the rotor is spinning, the LDR's resistance is high; and

for the rest of the time, its resistance is low.

The resin disc was attached with four screws to a short piece cut from an

old broom-stick. A hole of an appropriate size was drilled through the

centre of the assembly so that it would be a snug push-fit on the metal rod

chosen for the axle. When it turned out not to be quite as tight a fit as

I'd hoped, I included the fibre part of a tap washer in the assembly to

improve matters. (This is just barely visible in the right-hand photograph

above. You can see it better in the final photo in this page.)

Part of the barrel from an old ballpoint pen was used as the distance-piece

between the piece of broom-stick and one of the bearings, as can be seen

quite clearly in these photographs (especially the right-hand one).

In the left-hand photograph above, you can see part of a hardboard disc on

the far end of the axle. This corresponds to the flywheel in the earlier

diagrams. It has its own points of interest; more about it later.

The crankshaft arrangement shown in those earlier diagrams was not used.

Instead, another small hardboard disc with a central hole, and another hole

drilled near the circumference to accommodate a suitable pivot made from a

piece of an old ballpoint pen, was fitted to the near end of the axle as

seen in the left-hand photograph above. (The small blue circle in the centre

of the disc is also a part from a ballpoint pen, included to improve the

disc's grip on the axle.)

The blue object used for the armature is just the handle of an old

toothbrush! I simply cut off and discarded the head, and drilled appropriate

holes in the ends of the handle.

(You've probably noticed some other bits'n'pieces in the top-left quarter

of the right-hand picture above; don't worry about these for the moment -

we'll get back to them soon.)

For the solenoid itself, I used wire which had originally been about half of

the primary winding of an old soldering-iron transformer which I had

dismantled earlier. (Visit my

synchronous wheel

page to see what happened to the other half.)

Originally, I wound the wire onto part of the plastic barrel of an old

ballpoint pen (probably the same one which had provided the distance-piece

mentioned earlier). However, this turned out to be a bad idea. In use, the

solenoid became rather hot, and the plastic tube melted! This led me

to two conclusions: firstly, I was going to need to make the solenoid from

more robust components; and secondly, whatever the solenoid was made from,

it was going to get hot during use, and I would be well advised to install

some sort of automatic switch-off system. (This second point ultimately led

to the use of a thermostat switch - more on this weird saga later!)

Eventually, I used an 8.4cm piece of chrome-plated brass tube which had once

been part of a telescopic antenna on a small B&W television. (Again, check

out my

synchronous wheel

page to see what happened to other lengths cut from this old antenna.)

I had originally used a couple of little wooden blocks to support the

plastic tube, before it melted. Now, I obtained a piece of 1cm-thick

aluminium plate, about 11cm x 5.5cm, and cut it into two approximately

square halves. Having drilled a hole in the centre of each to accommodate an

end of the tube as a snug fit, I assembled the structure and wound the wire

on. I used a couple of pieces cut from "L" cross-section aluminium brace to

attach the result to the base. Here is a view from above:

The ends of the winding were connected to two green banana sockets attached

to the right-hand support below the coil.

Remember the thermostat I mentioned earlier? Here you see it for the first

time, clamped to the coil. (Just ignore it for the moment, okay?)

Also, here you get your first look at the iron core which moves backwards

and forwards within the solenoid when the engine is running, and which

operates the rotor via the amazing blue toothbrush-handle armature!

The core was made from an odd object I found lying around in my "junk"

collection: a large iron nail with a circular flange a short distance from

the point. I cut the head off and tidied up the cut end with a file. I found

a small piece of plastic shaped like a tube closed at one end (probably yet

another part of an old ballpoint pen!), and found that the point of the nail

fitted tightly in the open end. There was a small hole in the closed end,

just big enough to allow a small bolt to be screwed in, thus tapping its own

thread. The hole in the solenoid end of the toothbrush armature was made

just big enough to allow this bolt to pass through easily.

Now: more detail on how the LED / LDR combination controls the action.

The simplest thing to do would be to put the LDR in series with the

solenoid. It might work; however, the resistance of the LDR is still around

80 ohms when it's illuminated - quite a bit higher than that of the

solenoid's coil. This means that much of the available power will go into

heating the LDR, quite possibly damaging it - and not going to the coil,

where it's wanted. So we'd lose twice.

No: there's a much better way. Instead of using the LDR as a series resistor

for the solenoid, I used a 2N3055 NPN power transistor, employing the LDR -

and a few other components - to control that. As it turns out, this

protects the LDR from high currents, as well as getting plenty of power to

the coil. The 2N3055 is a fairly sturdy device, quite adequate for

controlling the solenoid's power requirements.

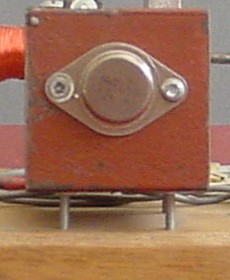

Because the transistor is being called upon to conduct a fairly heavy

current, I've mounted it on an L-shaped bracket cut from the end of a long

heavy iron brace, to act as a heatsink. This is probably overkill; but it's

better to be safe than sorry...

Here is the transistor mounted on its heatsink, both from in front and from

behind:

The base is connected to an old-fashioned 200 ohm resistor (and you know

where I found it, don't you?

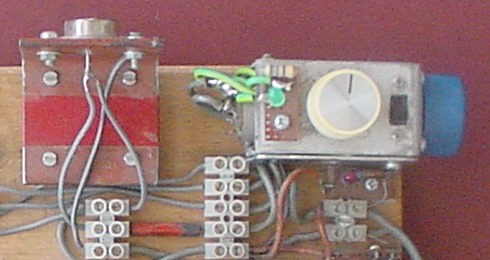

In this picture, taken from above the model, you can see the transistor on

its heatsink; the 200 ohm resistor (red with a black band, connected between

two terminal blocks); and a metal box which contains the 5K potentiometer.

Note: the blue knob at the right controls this 5K "pot", which has a long

shank. The pot itself is mounted in the left-hand end of the box. (The other

knob, on top of the box, controls another potentiometer which will be

discussed shortly.)

At this point, all the essential items required to make the basic engine

have been described. Here, then, is a circuit diagram for the original

version of the project:

(The power switch in the positive rail is on the back of the 5K pot.)

I ran it off my

old black power supply

with my home-built bridge rectifier, set to the maximum voltage (about

27V). It worked reasonably well. As expected, the coil became quite warm,

which ultimately led me to think of a way to include an automatic

temperature control using a thermostat. However, another issue began to play

at the corners of my mind. Although the overall performance was not too bad,

there was room for improvement: the engine seemed to run "a bit rough".

The first thing to do was to build a flywheel. This turned into a little

project in its own right. It started out simply as a circular piece of

hardboard mounted on the far end of the axle, but it acquired a bit more

personality later - more on this shortly.

Even with the flywheel, I felt that it should be possible to make the engine

work more smoothly. I placed more black tape on the transparent disc, so

that light would get through for a bit less than half the time. This

was because the solenoid was obviously staying on for a bit too long, and

preventing the rotor from free-wheeling as well as it should for the second

half of the cycle. This also helped to some extent; but I still believed

that it should be possible to do even better.

I started experimenting with extra resistors between the 5K pot's wiper and

the negative rail. This had a marked effect, and ultimately led to the

inclusion of a 1K linear pot. For different settings of the speed control

(5k pot), this gave a "fine-tune" control. Not a perfect solution - a bit

clumsy - but interesting, and not too difficult to implement.

I built the 1K pot into a small metal box, which now houses both pots and a

small double-pole slider switch. This was included for flexibility: the 1K

pot could thus easily be switched in or out of circuit, as required. I used

the second pole of the switch to run a green LED in series with a 560 ohm

resistor to act as an indicator, showing at a glance when the 1K pot was in

circuit - and also because I just like coloured LED's everywhere!

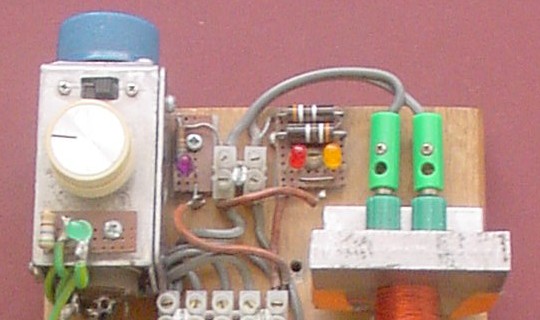

While on the coloured LED "kick", I included two more LED's - one orange and

one red - each with its own 390 ohm series resistor. The orange one glows

strongly when the transistor is on (and the solenoid is pulling); the red

one glows strongly when it's not. I found that when the fine-tune control

was used to give maximum smoothness, these would flash to approximately

equal brightness, thus giving a good visual indication of correct setting.

I also included one more LED: a white one, coloured purple with a felt pen,

in series with a 680 ohm resistor, to act as a pilot light for the entire

unit.

Here is the circuit diagram for the unit with all these features built in:

Now: as promised, a bit about the flywheel.

Ever the light-show freak, I decided to embed a white LED into the flywheel.

This necessitated an independent power supply to run it. I installed an AA

cell holder on the back of the flywheel, and placed a small 12V battery and

a 560 ohm resistor inside it. A small slider switch was installed. When this

simple circuit is switched on, and the engine set in motion, a ring of white

light appears. (This looks really good in the dark, with all the other LED's

glowing at the same time.)

Here are photographs of the flywheel, from in front and behind:

Because of the weight of the battery, the flywheel is not perfectly

balanced. I've put this fact to good use by arranging that, when the engine

is switched off, it comes to rest with the armature in a good position to

re-start it when power is re-applied. (I've found that the engine runs

better when set up to rotate anticlockwise, as seen from the front.)

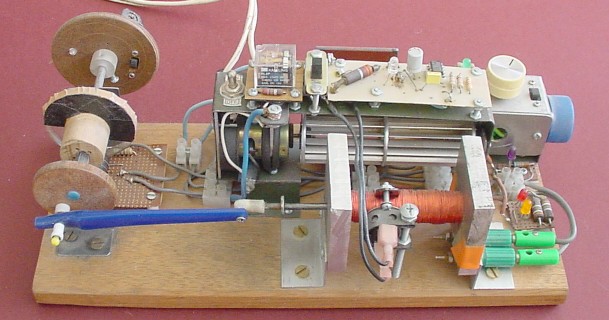

Here is a photograph of the entire model, seen from in front and slightly

above:

Here's a 10-second mpeg movie (921Kb). I start the camera; my wife switches

on the power supply (left, off-screen) and goes around behind me (you'll

notice a shadow effect as she moves through the light from the window); and

then she turns up the speed-control potentiometer to maximum. (The other

potentiometer, used for "fine-tuning" the engine's performance, is set to a

position which is an acceptable compromise for the engine's speed between

the minimum and maximum settings for this movie.) The rotor spins

anticlockwise, as can be clearly seen for the first few seconds; as it picks

up speed, the camera's strobe effect makes it seem to rotate clockwise:

sol-eng1.mpg

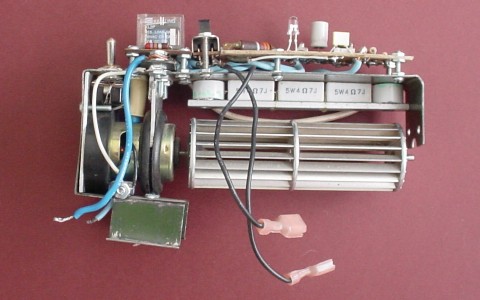

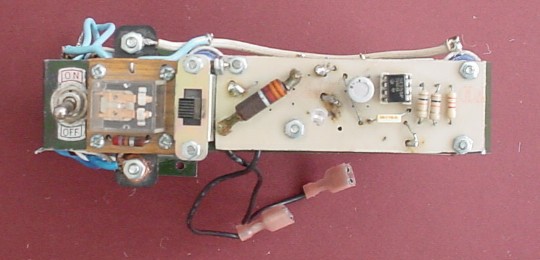

Next (also as promised) some comments about the thermostat-controlled

cooling system.

I went a bit crazy with this. The basic idea was to use a fan from an old

hand-held hair-dryer to blow air over the solenoid and thus cool it down.

Here are two pictures of the fan unit, from in front and above:

Here we go - fasten your seat-belt!

You may have noticed a small U-shaped white wire link joining two

terminal-block connections together, near to the power terminals (red and

black) on the main unit. These connections are marked A and B on the circuit

diagram. If this connection is broken, the yellow LED and the LDR are

isolated from the positive rail, so that the transistor is switched off and

the solenoid draws virtually no power - thus the engine stops.

You'll notice that there are two switches on the fan unit. The left-hand one

(with ON and OFF markings) is an SPST (single-pole single-throw) toggle

switch which connects between A and B when the fan unit is installed. This

gives an immediate manual control over the engine's operation.

To the immediate right of this switch is a DPDT (double-pole double-throw)

relay. One pole's "normally-on" contacts are wired to A and B also, so that

if the relay switches on (and the SPST switch is in the "OFF" position), the

engine will stop. (If the switch is in the "ON" position, the relay's effect

is over-ridden, and the engine will continue to operate.)

The "normally off" contacts of this pole operate the fan. When the relay

switches on, it may in turn switch the fan on - depending on the position of

another switch just to the right of the relay.

This second switch is a DPDT slider switch with a central OFF position. With

the slider in that central OFF position, the relay stays off even if the

thermostat triggers. However, with the slider pulled toward you, the relay -

and fan - will come on if the thermostat triggers.

If the slider is pushed away from you, the relay and fan switch on whether

the thermostat has triggered or not.

All this requires only one of the slider switch's poles. The other pole is

used to control a little electronic circuit, which takes up the rest of the

space on top of the fan unit.

This circuit is an astable multivibrator, based on a 555 timer IC, which

flashes a blue LED (this appears clear when off). With the slider in the

central OFF position, the circuit is off and the LED is not illuminated.

With it toward you, the multivibrator is switched on and the LED's cathode

is connected (vai a 2.2K current-limiting resistor) to the 555's output (pin

3) by means of the relay's second pole "normally closed" contacts. The LED

then flashes (about once per second).

With the slider pushed away from you, essentially we introduce a bypass for

the thermostat, so that the relay switches on and its second pole's

"normally off" contacts connect the LED's cathode directly to supply

negative, so that the LED glows continuously. (Recall that the relay's first

pole is then operating the fan.)

The effect of all this is that, with the slider towards you, the fan is in

"standby" mode with the blue LED flashing to indicate this. When the

thermostat triggers (or, equivalently, when the slider is pushed away from

you), the fan operates with the blue LED shining brightly as it does so.

(You are following all this, aren't you?)

To summarize:

The thermostat switch (clamped to the coil) is normally open, and closes at

about 60 degrees C (quite hot!). So, when the coil gets hot, the thermostat

triggers, thus switching on the relay. If the slider is toward you (so that

the blue LED is flashing) when the thermostat triggers, the fan will operate

and the blue LED will glow continuously. When the coil has cooled down, so

that the thermostat clicks off and the relay contacts return to their

"normally off" condition, the fan stops and the blue LED flashes again. If

the slider is away from you, the fan runs and the blue LED glows

continuously. The SPST toggle switch determines whether the engine runs or

pauses while the fan is operating.

A couple of final points:

As mentioned, the engine requires the highest (or at least the

second-highest) voltage setting of my

old black power supply

. For this reason, it was necessary to include appropriate series resistors

for all the LED's (including the blue one), the power connection to the 555,

and the fan.

The 3.3K resistor (the big one at extreme left of the 555's circuit board)

connected to supply positive takes care of the 555's power requirements; and

that resistor and the additional 2.2K resistor (at extreme right) make

things okay for the blue LED.

The fan is in series with three 5-watt resistors, each 4.7 ohm (for a total

of 14.1 ohms). Since these get quite hot when the fan is running, I've

arranged for the fan to blow over them as well as over the coil, thus

solving both problems at once.

Pretty neat, huh?

Here's the overall circuit diagram for the cooling system:

I'll tell you what: in the dark, with the cooling system on standby - so

that its blue LED is flashing - and all the other LED's (including the

flywheel's white LED) doing their respective things, this project looks

just great.

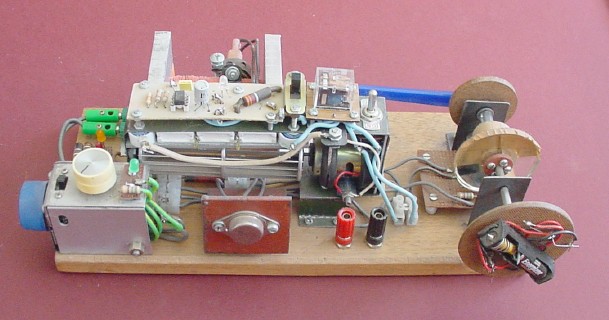

Now, two pictures of the engine with all its components installed, one from

in front...

... and one from behind:

Looks a bit like the old paddle steamer from "Showboat", doesn't it?!

So, what's it all for?

Well, if nothing else, this project shows how an essentially simple idea can

grow into something far more complicated than it has any right to be! But

it's all OK if it's interesting, fun, and part of a learning process.

My home page

Preliminaries (Copyright, Safety)

My single-solenoid electric engine

(ca. 2002)

This diagram shows the transistor's pinouts. I've used it in its most usual

cofiguration in this circuit: the emitter is connected directly to the

"negative rail"; the collector is connected to one end of the coil (the

other end of which is connected to the "positive rail"); and the base is

connected to reflect what's happening in the LDR.

This diagram shows the transistor's pinouts. I've used it in its most usual

cofiguration in this circuit: the emitter is connected directly to the

"negative rail"; the collector is connected to one end of the coil (the

other end of which is connected to the "positive rail"); and the base is

connected to reflect what's happening in the LDR.

). The other end of

this is connected to the wiper of a 5K linear potentiometer; one end of

this is connected to the negative rail and the other end to the LDR. The

other lead from the LDR is connected to the positive rail. Thus the LDR and

the potentiometer together act as a potential divider, which allows

the voltage on the transistor's base to be controlled over a fairly wide

range, thus providing a speed control for the engine. (The 200 ohm resistor

is probably not strictly necessary, but was included as a current-limiting

device just in case.)

). The other end of

this is connected to the wiper of a 5K linear potentiometer; one end of

this is connected to the negative rail and the other end to the LDR. The

other lead from the LDR is connected to the positive rail. Thus the LDR and

the potentiometer together act as a potential divider, which allows

the voltage on the transistor's base to be controlled over a fairly wide

range, thus providing a speed control for the engine. (The 200 ohm resistor

is probably not strictly necessary, but was included as a current-limiting

device just in case.)

Return to Electromechanical models sub-menu

Return to Electromechanical models sub-menu