This page added on Friday, 10th July 2009

+

+

+

+

+

As mentioned in the page about my first attempt to build a motor of this

type (see the link above), the word "monopole" as used in this context

does not mean that I believe in the existence of particles which

have the character of either a north pole or a south pole. (I suspect that

such things don't exist; however, I'm not dogmatic about it. See my

second page on

electromagnetism,

about four-fifths of the way down, to read some of my earlier comments on

the subject). The term "monopole" in this context has to do with the fact

that these motors rely heavily on repulsion between either two "north

poles" or two "south poles" of "ordinary" magnets - one, an

electromagnet; and the other, a permanent magnet.

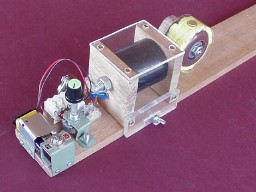

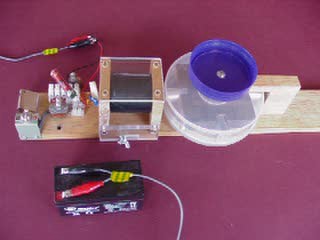

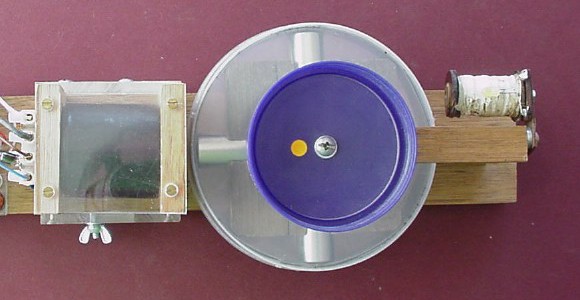

The photograph you see above has already appeared before in this website

in my oddly-named

2

The strange-looking gizmo it depicts is my second attempt to make a motor

of the type described by John Bedini (JB), a US electronics engineer who

claims to have been building such things since 1984.

CAUTION:

There is some risk associated with motors of this type. As JB mentions in

his own writings, it may be possible to receive an electric shock from

them; however, perhaps more significantly, there is a danger of physical

disintegration! These motors can spin very fast, and if they're not

well-built, it's possible that one or more of the magnets attached to the

rotor may go flying off in unpredictable directions. [This hasn't happened

with my first monopole motor (see the first link above), but it did

happen with my second one, which is the subject of this page - and I

consider myself very lucky that my eyes (especially my one "good" eye)

weren't in the "firing line" at the time (more details shortly.)] Or, of

course, the whole rotor may become detached and go spinning out of control

if the motor itself is not sufficiently sturdily built. So, if you build a

motor of this type, be careful; having drawn attention to the possible

dangers, I cannot and will not accept any responsibility if something goes

wrong.

If you don't yet know anything at all about these monopole motors (or

"Bedini motors", as they are also called, after their inventor), may I

recommend that you do, in fact, visit my page (whose link appears above)

about my first motor of this type. That page also contains links to other

websites which provide a good background to the topic.

This second motor is a work in progress. I still have in mind to modify it

in order to improve its performance, even (perhaps!) to the point where it

may actually display the phenomenon known as "over-unity", meaning that

it's tapping into more energy from the zero-point field than it's using

from its battery or other "normal" power-source. I'm not there yet; but I

haven't given up on the idea, either.

Originally, the motor didn't look much like the photo at the top of this

page at all! It's undergone a number of transformations. The following

four photos, of its original incarnation, were taken on 11th November 2008

(you can click on them to see 640×480 versions):

As you can see, it featured another skateboard wheel with four small

NdFeB magnets attached around its rim in the same way as for my first

monopole motor. (This time, just a single wheel was used, attached to a

little wooden pillar I made up specially for the purpose.) Also, the

circuit - built into a five-connector terminal block - was identical with

the one in my first monopole motor, with a 1K linear potentiometer, a

10-ohm resistor, a 1N4148 diode, and a 2N3055 transistor, all mounted in

exactly the same way, with the terminal block mounted on a little wooden

plinth screwed to the base. (There was also an on-board 9V battery,

initially, although this was later removed.) Recall these two diagrams

from my first monopole motor's page; they apply here also:

You may have noticed, in the above photographs, a two-connector terminal

block in front and to the right of the main circuit terminal block; that's

just there to connect the two soldered wires from the switch to the rest

of the circuit. (Experience has taught me to keep soldering to a minimum,

as I'm not really very good at it! Hence the extensive use of terminal

blocks in my projects.) That's a minor difference from my first monopole

motor.

But what is substantially different about this second motor is the

coil.

In my page about the first of these motors, I mentioned that, when I came

to build the second motor's coil, things went rather badly wrong. The time

has now come to tell the story...

The main reason for wanting to build a second monopole motor at all was to

see if I could in fact successfully create one which would charge a

battery - even, perhaps, well enough to qualify as an "over-unity" device.

Having had a bit of a look around the web to see what I could find out

about these Bedini motors, I'd noticed a couple of things:

1.

The coils were often wound onto rather small-diameter formers, with room

for only thin cores - in contrast to my first motor's coil, which was

wound onto an old solder spool with quite a large central hole (about 2cm

in diameter) which thus required a fairly large-diameter core (as detailed

in my page about that motor's construction);

2.

At least one possible scheme for charging a battery with a

motor of this type involved a third winding on the coil, in

addition to its drive (or power) winding and its

trigger winding. This third winding, apparently, would act somewhat

as a secondary winding (as in a transformer) which would experience a

voltage across it as a result of the drive coil's action. The output from

such a winding (with some rectifying circuitry) could, in principle, be

used to charge a battery. If the motor was running from one battery, and

if this third coil could somehow be persuaded to charge a second battery

faster than the first battery ran down, you'd have an over-unity device!

(Click

here

to visit a web-page which presents a circuit for such a "Two Battery

System", near the bottom of the page. The third winding, labelled "Sec

Feedback Coil" - the green one - is what we're talking about here.)

So I decided to build a coil - just a bifilar two-winding coil initially,

as in my first monopole motor - onto a former with a small-diameter

central hole and enough room to add a third winding later, if and when it

became appropriate to do so.

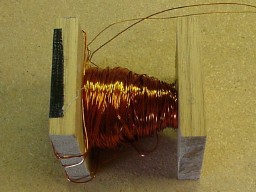

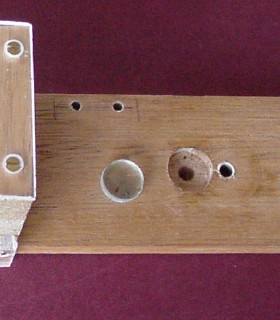

I used an old plastic crayon-barrel as the central tube, and cut two small

square pieces of timber to act as the end-pieces. I drilled central holes

in these two wooden pieces, just big enough to take the crayon-barrel as a

tight fit. I wound some gaffer tape around the tube, and set the whole

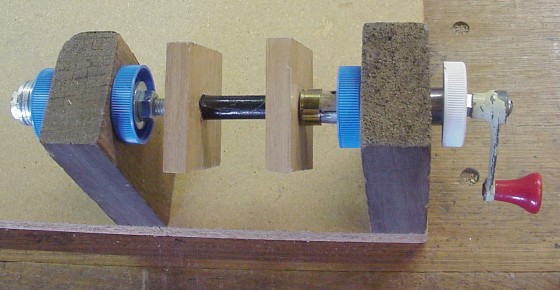

thing up in my winding jig as you see here:

Then I started winding the two wires on together, just as I had earlier

for the first motor.

At first everything seemed to be going well. But at some point I noticed

that the left-hand end-piece was moving. Clearly, it wasn't as tight a fit

on the tube as I'd thought! The wire was pushing it outwards.

I kept winding cautiously, but eventually I realized that I had a serious

problem as the situation became worse. I was faced with the choice of

trying to unwind the wire already wound, then reinforcing the former and

starting again - or taking it off the jig as it was, holding it carefully

in one hand and continuing to wind manually with the other.

The first wasn't really an option. It seemed clear that any attempt to

unwind the wire and install the two strands back onto their respective

feeder spools - or even onto a single spool, probably - would almost

certainly result in an unholy tangle in very short order. So I embarked on

the unpleasant task of winding by hand, as quickly but as cautiously as

possible!

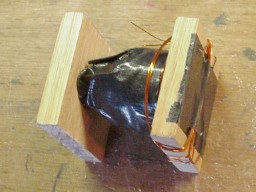

I eventually wound a total of about 600 turns on, trying as hard as I

could to keep most of the wire toward the "good" end of the former. The

result was an ugly conical coil. Almost as soon as I'd finished, I wrapped

it up in gaffer tape to try to prevent it from basically falling apart.

Here are some photographs of the resulting monster (you can click on them

to see 640×480 versions). Don't laugh!

One thing that was very clear was that this was far from being a

high-quality bifilar coil. The early part of the winding was probably

quite good; but when I had to finish it in an angst-ridden state by hand,

I can tell you that the individual strands went all over the place, hardly

staying side-by-side at all. Oh dear!

To be honest, I thought that the coil might end up as a complete waste -

but, as you'll soon see, I was able to get some good use out of it after

all. (No way, however, was I going to try to get a third winding

onto it!

However, I learned one valuable lesson from this: if you are going to wind

a coil onto a former you've made yourself, make absolutely sure

that you've made it well enough to withstand the process. (In my case, I

did have a large bolt through the centre, but neglected to set things up

so that I could screw a corresponding nut tightly against the opposite end

of the former to hold it firmly in place, relying instead on friction. If

I'd taken the extra trouble, I probably would have obtained quite a

respectable result. Next time...)

To stabilize the coil, I cut three pieces of perspex sheet to hold it all

together: a piece to be attached to the top by a brass screw at each

corner, and two smaller pieces to be attached to the sides, near the

bottom, by brass screws at each end. I made these two side pieces wide

enough to fit over the edges of the base-board, and cut slots in them so

that they could slide along screws in the sides of the base-board,

secured on the near side by a wing nut.

I cut a piece of cardboard tube from an old pepper-shaker, just long

enough to fit over the coil, covered it with gaffer tape, and slipped it

over the coil before fixing the whole unit together - partly to make it

look rather good, and partly (if I'm honest) to conceal the evidence!

You can see the finished coil unit in those four earlier photographs of

the motor, above. (Note from those photos that I did indeed use a large

bolt and nut for the core.) So: with the motor completed, I switched on, gave the

wheel a spin...

...And it didn't work!!!

It nearly worked. The wheel spun half-heartedly through a few

revolutions, looking as though it was "trying" to pick up speed - but,

ultimately, it slowed down and stopped. It just "conked out".

I tried several times, to no avail. I assume it was because of the

disastrous coil. I even tried using a piece of ferrite rod - just like the

one I've used for my first monopole motor - for the core, still without

success.

So - what was I to do?

Well, I did what any good inventor does, when faced with a setback. I used

my initiative.

I had some larger NdFeB magnets "lying around". (I'd bought them some

years previously, when I had an inkling that I was going to be getting

into projects that would need them. They're the same type as those used in

modern Faraday torches - click

here

to see my page about such things.)

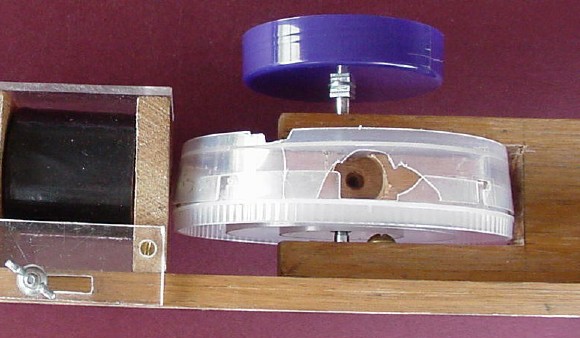

I also had some empty CD boxes, having bought them from

my favourite Launceston junk shop

a few years back, suspecting that they'd come in useful some day.

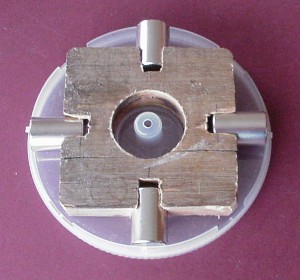

The idea was to fix the magnets in place inside the CD box, equally spaced

around the rim, and all with the same pole facing outwards. (As it turned

out, they were placed so that they attracted the "N" pole of my little

compass, so that this became a "south pole motor" - just the same as my

first monopole motor.) To hold them immobilized inside the box, I used a

piece of old timber which was somewhat the worse for wear (having been

outside in my back garden for ages) but which was pretty much ideal in

terms of size. I cut a square piece off the end and drilled some suitable

holes: a large central hole (using a hole saw), as there was a flange

inside the box which had to be avoided; and four smaller holes to

accommodate the magnets in the wooden block's edges (I used a spade drill

for this).

(Actually, the piece of wood was so grotty that it fell to pieces while I

was working on it, and had to be glued back together! But I persevered

with it, because in so many ways it was ideal, notwithstanding its age and

condition - and my decision was vindicated by the eventual success of the

rotor. Not pretty, but functional.)

It was quite a difficult job to get them to stay in position. Putting the

last one in was a real battle - one momentary loss of concentration, and

the others would be jumping out all over the place, with a risk of

considerable damage if they should clang together violently. Somehow, I

got them in.

Notice in this picture, and the one above, that there's a small hole

drilled in the centre. This is to accommodate a 75mm-long, 3/16"-diameter

bolt which would form the wheel's axle. I used a short piece of very tough

plastic tubing (the inside end-piece taken from an old crayon) similarly

drilled and pushed into the box's central spindle from below, to act as

the lower grip for the axle.

Note from the first of those two photos that there are four small gaps in

the box's rim (the corners of the wooden block are lined up with them in

that picture). In fact, with the lid partially on, I rotated the block so

that the magnets lined up with those gaps instead, on the principle that

they would stay located that way and thus the block/magnets combination

would not be free to rotate within the box. Hence the magnets were then

actually pressing on the inside of the lid, rather than the

box. (The reason for taking the trouble to point this out will

become clear shortly.)

I drilled a hole in the lower limb to take a 25mm-long, 1/4"-diameter

brass bolt, to secure the bracket to the base via a 1/4" brass nut.

As mentioned, the rotor's axle was to be a 3/16" bolt, 75mm long. To act

as bearings, I used four short pieces cut from an old telescopic TV

antenna: two just wide enough to slide easily over the bolt, and two

slightly wider to fit over the first two. These wider pieces were to be a

snug fit in the wooden bracket's top and bottom holes respectively.

I very carefully drilled the lower part of the bottom hole just

wide enough to accommodate a 3/16" dome nut, to be screwed onto the end of

the axle. (The hole's diameter was very slightly larger than that of the

dome nut, so that there would be no contact.) When everything was set up

properly, the round tip of the dome nut would protrude just a millimetre

or so beyond the bottom of the bracket; and also the dome nut could be

pushed up inside so that its tip was a millimetre or so above bracket's

bottom surface. Thus, with the completed bracket/rotor assembly screwed to

the base, the dome nut's tip would be level with the base's top surface

and the rotor would be free to rotate unimpeded.

The bluish-violet object, lock-nutted firmly to the top of the axle, is

the lid from a jar of hair-gel, as once used by a junior member of my

family. I drilled a central hole and installed it upside-down, not really

being quite sure why at the time (basically it just looked "cool"!). In

fact, it turned out to be a good idea, as you'll soon see.

The rotor iself was initially mounted onto the axle by lock-nutting pairs

of nuts both above and below, along with some washers. This was a

trial-and-error procedure; several modifications were made over time to

find the best way to achieve this. (There wasn't much room to play with,

to tighten up those nuts. Fine-nosed pliers played a major part in what

was quite a tricky process!)

Eventually, however, I found what seems to be the perfect soloution. We

now live in the era of the

"nyloc nut"

- a nut which incorporates a small ring of nylon. When screwed tightly up

against something, these grip the bolt very firmly, so that one of them

does the same job as two lock-nutted ordinary nuts. Just one on top of the

rotor and one under it are all that is necessary to hold it firmly to the

bolt. This makes the assembly process a great deal easier. (Apparently,

it's recommended to use washers with these nuts; but I haven't done so,

and there doesn't seem to be a problem.)

Here's a side view of the entire bracket/rotor assembly:

Next - some details of how it was fixed to the base.

As mentioned, a 25mm, 1/4" brass bolt (with matching nut) was involved. (I

used brass, rather than steel, because it was fairly close to the rotor's

magnets, and I didn't want it to have any effect on the motor's

operation.) In addition, a brass wood-screw was used to hold the body of

the bracket firmly to the base; this was screwed up from underneath.

Here's a photo of the underside of the base:

The head of the wood-screw can be seen between the square black feet at

the right-hand end. Note that the brass nut which is screwed onto the 1/4"

brass bolt is set into a small recess, made with the aid of a spade drill.

Also note a small hole just to the left of the nut; this was made as part

of the process of drilling a similar recess in the top of the board, to be

explained next.

(Finally, note two countersunk holes near the lower edge in the photo.

These were the holes for the two screws by which the small pillar which

held the skateboard wheel was originally attached to the base.)

The recess in the upper side of the board was made to take a small glass

disc. If you've visited my first

synchronous wheel

page, you'll have read how some years ago I came into possession of a

number of such discs from a former Launceston glazier. Much as in the case

of that earlier project, I used the disc - with a small amount of grease

on its top surface - to support the rotor's axle:

This formed an excellent bearing for the dome nut on the lower end of the

axle.

So now I had something to try out. By now, the coil's core was a piece of

ferrite rod, just as in the case of my first monopole motor. At some

stage, I also placed a small orange circular sticker into the hair-gel

lid, to serve much the same purpose as the small white sticker on my

synchronous wheel: to give some indication of the motor's speed, when

viewed under a fluorescent light. (I also placed a similar red sticker

onto the rotor itself.)

My first experiments with the new motor were conducted on Saturday, 15th

November 2008, using my small 12V gel battery connected to the 9V battery

clip via one of my crocodile-clip leads. I also replaced the trigger

circuit's 100-ohm series resistor with a large old-fashioned resistor from

among my Dad's old things. (That's the red cylindrical object in the

photograph below. I measured its resistance at 315 ohms.) Initially, I

hadn't yet placed the red and orange stickers.

With the motor at maximum speed, I switched off and filmed the early part of

the slowdown - click

here.

(Again, if you've seen the movies toward the end of my second

synchronous wheel

page, you'll probably recognize the style!

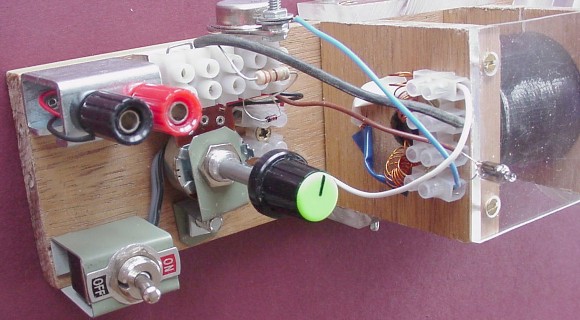

By Thursday 20th, I'd dispensed with the idea of using an on-board 9V

battery. (From the first of the two photos above, you can see its clip -

made from the sliding metal cover of a defunct 3.5" floppy disc - at the

left-hand end of the base; this was now removed.) I installed a pair of

banana sockets (red and black) in order to run the motor from an external

power source - either a gel battery, or my

old black power supply

and bridge rectifier.

Also, by now I'd decided to make a series resistance greater than 100 ohms

a permanent feature in the trigger coil circuit, eventually settling on a

normal-sized modern 330-ohm resistor. Again, if I remember rightly, at

some point I managed to burn out the potentiometer (which is probably what

really decided me to use that larger-value series resistor). It didn't cause

a problem, because the motor's "sweet spot" was well within the new range.

(Note that the potentiometer in the following photo is a different one

from that in the earlier pictures.)

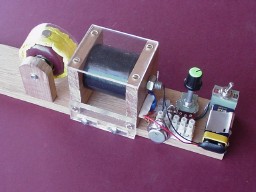

Furthermore, by this time I'd installed a four-connector terminal block

onto the left-hand side of the coil to tidy up its wires, using blue and

white tape to aid in identifying the particular ends of the windings -

just as I later did in my first monopole motor.

Just one other thing - note the small neon light connected into the coil's

terminal block; more about this later.

+

+

+

+

+

By now, I was running the machine from my old black power supply and

bridge rectifier on a regular basis, with the power supply's voltage set

to 14V AC (thus providing nearly 20V DC from the bridge rectifier). I

found it interesting to lower my head to bench level and observe the edge

of the rotor at close quarters. From oscilloscope traces (about which more

later), I'd figured out that the rotor was regularly spinning at well over

4,000 rpm - and I was trying various tricks to get it to spin even faster.

At some point while the motor was running, I squirted some silicone spray

lubricant into the bearings. I was alarmed to hear the speed increase very

rapidly, and reached over to my left to switch the motor off - too late!!!

There was a cracking sound, and one of the magnets shot out of the

rotor, hit me in the tummy, bounced off and promptly disappeared - while

the motor ground to a very shaky halt over a few seconds.

Fortunately, my tummy is pretty well padded, and I wasn't hurt. However,

it's a sobering thought that not long before, I'd had my eyes level with

the spinning rotor...

I think someone was looking after me that day!

After I'd recovered my wits, I looked carefully at what was left of the

rotor and noticed that the centrifugal effect of all three of the

other magnets had been causing damage to the box (to its lid, mainly, as

that was what the magnets were pressing against). Any one of them

may have been just about "ready to go".

Here are photographs of the rotor taken from the perspective of each

magnet position in turn, for comparison. (Click on them to see 640×480

versions.)

That still left the problem of: where did the missing magnet go?

It could have shot across my garage/workshop and broken the window; or it

could have hit the concrete wall; or it could have headed for and damaged

my car - any number of things. There was the distinct possibility that, if

it had hit something hard, it could have disintegrated into lots of sharp,

dangerous, strong little magnets, scattered all over the (rather untidy)

area.

But luckily, it didn't. It hit my ample midriff, probably thereby losing

quite a bit of its kinetic energy, and then went - where???

I eventually found it. It had stuck itself onto my bench vice, completely

intact, remarkably without either causing or experiencing any damage at

all!

As I've said - I think someone was definitely looking out for me

that day.

At the risk of being tedious, again may I urge you to be very

careful if you are intending to build your own Bedini motors - or,

indeed, if you intend to undertake any form of potentially

dangerous experimentation. The health and safety of yourself and those

around you must come first. Think before you act; and never

take silly risks - it's just not worth it!

So - I was faced with the prospect of building a new rotor.

Fortunately, I had what I needed. I'd bought three CD boxes of that size

and shape, so I still had two left. This time, however, I was going to

make sure the rotor was reinforced, to (hopefully) prevent any further

accidents!

Among the many bits'n'pieces I'd found among my Dad's old things were some

rolls of strip metal. Most of these were attracted to magnets, and were

thus almost certainly iron; whatever they were, they weren't suitable for

this purpose because I needed something non-ferromagnetic. However, there

was one roll of strip metal which appeared to fit the bill perfectly.

I weighed the strip metal and obtained an estimate of its volume by water

displacement, and was thus able to get a good estimate of its density. I

did a Google search on metal densities and found that magnesium has a

density of 1.74g/cc. My density estimate was very close (just a little

lower).

I concluded that it was almost certainly magnesium, as there is no other

common metal with such a low density that also has good structural

strength. (I resisted the temptation to follow the example of Archimedes

and go running down the street in my birthday suit yelling

"Eureka!"

when I'd figured this out.)

The strip's width was ideal - it would just fit into the CD box. I cut a

piece long enough to go around inside the box twice, put it in, and then

placed the wooden block with its four magnets inside that. It was a

perfect fit.

I cut four small rectangles from a clear plastic fruit-juice bottle and

slipped them between the ends of the magnets and the magnesium strip, to

eliminate any possible corrosion which might occur over time as a result

of the difference in electrochemical potential of the two metals

(magnesium, and the nickel casing of the magnets).

I then put the lid on (which was quite a struggle, as things were now a

bit tight). With the axle-holes drilled and the tough plastic tube from

the original spindle installed underneath, I had a new rotor ready for

action - and, so far, it has stood up to the challenge very well!

(I didn't bother to put a red sticker onto the new rotor, as the original

one hadn't really been visible when the motor was running, being too close

to the edge and thus moving too fast to see.)

Initially, it appeared that the wheel might pick up speed - but it slowed

over about 20 seconds and then stopped, just as before. Maybe one day,

with a decent coil, it'll work...

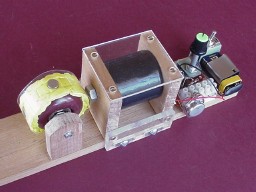

So I just went ahead and installed the new rotor. I also added an extra

feature.

If you've visited my page about my first monopole motor, you'll have read

about how I arranged for it to interact with an electromagnet with a

light-emitting diode (LED) soldered to its coil's ends. That electromagnet

was one of two that had once served as chokes in a battery eliminator for

my first transistor radio, nearly four decades earlier; the other one was

now called upon to perform a similar function in this project.

It's attached to the top of the rotor's bracket via a small piece of

laminated plastic and a couple of screws. (You can just see the yellow LED

against the white tape in which the electromagnet is wrapped.)

The electromagnet can swivel up (on top of the bracket) or down (behind

the bracket). When it's up, it has little or no interaction with the

rotor's magnets; when it's down, the magnets induce a voltage sufficient

to light the LED. (There is then a considerable braking effect on the

rotor.)

Over time, I noticed that the rotor's bearings were becoming more noisy,

presumably due to wear. The top one, at least, was reasonably accessible,

and I made an improvement by drilling the hole a bit larger and bolting a

piece cut from the end of an old brass mortise lock's face-plate onto the

top of the bracket, so that its original screw-hole was centred over the

hole in the bracket. A slightly longer piece cut from the larger of the

two tubes from the TV antenna was a snug fit in the screw-hole, and

replaced the original piece. I used 3/16" brass bolts and dome nuts to

secure the plate.

I'm still not sure how, if at all, I can do anything to improve matters at

the lower bearing. If I could find some way to secure the outer metal tube

firmly inside the bracket's hole, it would probably help. The way it is,

sometimes it remains stationary inside the hole; but sometimes it spins

within the hole - outside the smaller tube - creating a vibration or

"buzz" which represents wasted energy. (It's more of a nuisance than

anything else - it can stay in the too-hard basket for now.)

Both types have 3/16" thread; but the axle's nut (left) was physically

slightly smaller, also brass but (apparently) chrome-plated.

Having overcome various setbacks and actually produced quite a reasonable

little project, even with its substandard coil, I began to wonder

if there was any chance that it may actually be possible to persuade it to

charge a run-down battery, at least to some extent.

As mentioned, I'd already discounted the feasibility of adding a third

winding to the coil. However, while hunting for information about monopole

motors on the web, I'd run across at least one other way to extract an

electrical output without the necessity for any further windings;

click

here

or

here

to see a circuit diagram for such a device.

So I decided to modify my second motor's circuit to make it somewhat

similar to the one shown in those web-pages.

Until then, the circuit for my second motor was almost exactly the same as

the one for my first motor. The "hardware" aspects - the coil, the rotor,

and the overall layout - were obviously quite different; but from a purely

electronic point of view, they were very similar. The main points of

difference were that the 10-ohm series resistor had been replaced by a

330-ohm resistor, and there was no longer an on-board battery, with two

banana sockets provided instead to allow external connection to a battery

or other DC power source.

Also, as mentioned earlier, I'd added a small neon light bulb, connected

between the transistor's collector and emitter. I'd read somewhere (I

can't remember where) that it's a good idea to do this, as it provides a

"sink" to discharge excess energy in the form of high voltages which can

otherwise damage components, the transistor in particular. (I'd already

"fried" one transistor!) The neon light is connected into the coil's

terminal block across the "blue tape" ends of the two windings.

The circuit diagram for the project thus far is as follows:

So now I added a 1N4007 diode and another pair of banana sockets into

which a battery may be plugged for charging. The following circuit diagram

shows these two new components:

There are three differences between this circuit and the one shown in the

above links: that circuit has a 100-ohm resistor (where I'd originally had

a 10-ohm resistor, later replaced with a 330-ohm resistor); I haven't

added an incandescent light bulb into the trigger circuit, as has been

done in the other circuit (apparently this is not considered essential);

and I've kept the original 1N4148 diode (the other circuit has a 1N4001).

I decided not to change these on the principle that one should add as few

new variables as possible when setting up a new experiment.

I located the new banana terminals at the front edge of the base-board. In

order to accommodate the new diode in a tidy way, I introduced another

two-connector terminal block which I mounted above the one which connects

to the switch.

I also added a four-connector block into the small amount of remaining

available space between the power terminals and the switch, at the

left-hand end of the base, and made connections to the points shown as A,

B, C, and D in the circuit diagram. I made four small wire loops and

connected them into the left-hand side of the terminal block. The purpose

of this is to make it easier to connect an oscilloscope probe or

multimeter etc. to various points of interest in the circuit while

testing.

You can see all these new features in the following photograph:

The question that arises is: how, if at all, can such a circuit charge a

second battery?

It's a very reasonable question. On the face of it, that's a very odd

circuit indeed. Note from the circuit diagram that, when the motor is

running, the negative terminal of the charging battery is connected to the

positive terminal of the power battery (or whatever other DC power source

is being used). Presumably, then, the circuit is somehow generating a

larger DC voltage across the charging battery than the applied

voltage at the power terminals. What's going on?

Note that it takes about 70 volts to "strike" a neon light. (Click

here

to see the 1.3Mb, 15-second movie.)

So it's clear that there is a voltage of at least 70V at the

collector/drive coil junction (B, on the circuit diagram) relative to the

power supply negative (D) - enough to make the neon light glow, quite

brightly. (In fact, that neon light, initially a clear little glass bulb,

quite quickly became clouded to a dull grey soon after I installed it, as

a result of metal vaporization and deposition on the inside of the glass.

The fact that its glow is still bright enough to be seen very clearly

through the darkened glass speaks volumes.)

Just by the way - I have managed to give myself a shock from the circuit

once. Sometimes, I've placed a finger on the body of the transistor (i.e.

its collector) to see if it's getting warm. On one such occasion, I got

quite a strong jolt from it! Why it happened then, but not at other times,

I don't know. (I've had a similar experience before from one of my other

little motors; visit

this page,

down toward the bottom, to read the details.) Luckily, no harm done, on

either occasion! Maybe this time I'll learn from the experience...

So that quite high voltage - rectified by a diode - is fed directly to the

charging battery. Does it work?

On Monday, 24th November 2008, I decided to give it a try.

It was down to less than half a volt. I tried to charge it using my

ordinary battery charger, to no avail. Apparently, I'd bought a real dud.

In his writings, JB claims to have resurrected sick batteries using

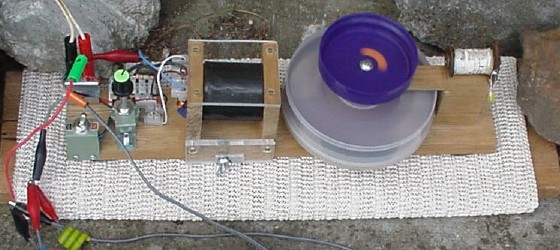

monopole motors. I decided it was worth a try.

At that stage, the neon light was in place, but I hadn't yet permanently

connected the second diode. I took my old power supply and bridge

rectifier out to the back garden, along with the motor, my multimeter, the

afore-mentioned second diode, the useless battery, and several crocodile

clip leads, and set everything up. The photo at the top of this page shows

some of the resulting arrangement; the following one shows the whole

set-up:

For the same reason, I placed the battery behind the tough wheelie-bin, just to

protect all the other bits and pieces from being blown to smithereens

should the worst happen.

I needn't have worried. I had it running out there for over three hours,

checking the battery's voltage every now and then with the multimeter.

Here are my notes:

Charging of sick 12V battery, 24-11-2008, using MPM2

Started at approx. 11:30 a.m. - battery initially at 0.478V. Charge voltage

showing at 32.6V.

At approx. 12:35 p.m., disconnected battery from MPM2 and measured 4.4V

(6.0V initially, dropping down over about a minute to a steady 4.4V)

Reconnected battery to MPM2 at approx. 12:40 p.m. Charge voltage at 27V.

At approx. 1:50 p.m., repeated above procedure and measured 4.4V; charging

voltage was 23.8V.

At approx. 2:50 p.m., voltages were 4.9V and 24.6V. Shortly after

switch-off, battery voltage had dropped to 3.2V. Later dropped to 2V.

Earlier I presented an mpeg movie which shows this motor running from

another small 12V gel battery. This one started life as quite a

gutsy little energy-source; but I think I damaged it by using it too much

and then neglecting to charge it (using my ordinary battery charger) soon

enough thereafter. The result is that its voltage went down to less than

10V, and it wouldn't charge back up to 12V (the charger's LED blinked,

indicating that it "thought" the battery was fully charged, when it quite

clearly wasn't).

On Saturday, 28th March 2009, I set everything up again outside (can't be

too careful) and put the motor to work trying to rejuvenate that small gel

battery (as before, parked behind the ubiquitous wheelie-bin, just in

case). I ran it for over two and a half hours, and the battery's voltage

went up from about 9.8V to about 10.3V - in increase of about half a volt.

Again, nothing spectacular; and it still won't respond to my

ordinary charger after the event - but it did manage to hang onto that

extra half a volt when I checked it two days later.

It's interesting to note that the charging voltage - as shown on the

multimeter - was about 12.7V (as compared to over 30V, on the earlier

occasion when I tried to charge the really sick battery), and that

the neon light didn't glow this time (which it had done with the other

battery).

From the notes above, it's quite clear that the charging voltage - as

measured on my multimeter - drops significantly as the battery begins to

charge up, seeming to indicate a definite resistance to being further

charged. I've no idea how to explain the actual figures in any detail -

how much of it is due to high-voltage spikes (i.e. high voltage) from the

motor, and how much is due to any low-voltage content (perhaps at a higher

current). Neither can I account for the fact that the neon light doesn't

glow when the charging battery is close to its nominal voltage.

Quite clearly, these are complex issues, and I can't draw any definite

conclusions. (Perhaps when I build a better coil I'll get better results.)

But it is interesting and fun to be engaged in my own modest

scientific research project!

Obviously, there's lots of room for serious research here - and I'm

probably not really equipped to do this properly. It is my fervent hope

that "mainstream science" will begin to take these and related phenomena

seriously very soon, hopefully in time to see a well-organized zero-point

energy industry adopted world-wide before it really is too late, and

damage from global warming due to the burning of fossil fuels becomes

permanent.

This is turning into another of my l-o-n-g pages, isn't it? However,

please bear with me - there's not too far to go. I'm deliberately going

into considerable detail, in the hope that you - and anyone else you tell

about it - will get involved and build your own monopole motor and then

find some way to go public about it, as I am doing right here, in the hope

that enough such activity will finally get the world's "movers and

shakers" to wake up and get behind ZPE research As Soon As

Possible.

A few details about what actually happens when this motor is operated:

(Click on the photo to zoom up on the oscilloscope screen.)

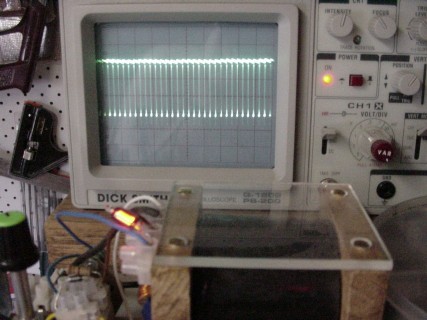

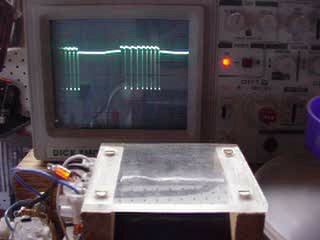

The oscilloscope's time-base is set to 2 milliseconds (2ms) per division.

Since there are 10 divisions (square-widths) across the screen, this means

that the beam makes one complete left-to-right sweep in 20ms. If you look

at the right-hand half of the screen, you can count 16 "spikes" occurring

over 10ms, or one-hundredth of a second. So the frequency of oscillation

is 1,600 Hz (cycles per second).

Since "concert pitch" ("A440", or A above middle C) is 440Hz, we can

calculate the approximate note produced by the motor as follows:

2n/12 = 1600/440 = 3.636363...

- or about 22 semitones above A440. This is a high G, nearly two octaves

above A440. (An octave is 12 semitones.)

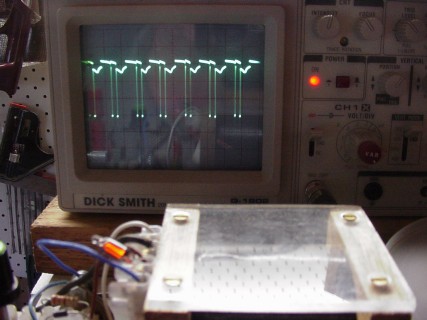

As it speeds up, the trace begins to take on the character of a standard

monopole motor waveform (see photos on my

first monopole motor

page for comparison).

The oscillations stop as a magnet moves away from the core, and recommence

as the next magnet approaches.

(Click on the photo to see a close-up of the 'scope screen.)

The speed of rotation can be estimated from the trace. The time taken from

a particular magnet's interaction with the coil to its next

interaction (count the "double-spikes" as 1, 2, 3, 4, 1) is about six

divisions, or 12 milliseconds. This corresponds to a rotational speed of

1000/12 = 83.333... revolutions per second, or 60×83.333... = 5,000 revs

per minute (rpm). (It's actually slightly faster, because the time per

revolution is slightly less than six divisions.)

Click

here

to see a 1.3Mb, 15 sec. mpeg movie showing the motor running at top

speed. A few seconds into the movie, I switch the motor off, and it begins

to slow down. Then I switch on again, and it speeds up again. What's

interesting is that the trace shows some electrical activity even when the

motor is off but still spinning. (In fact, the neon light even glows very

slightly during that time, but it's too faint to be seen in the movie.)

Note that, in all photos and movies so far in this page showing the motor

running from my old black power supply, I have it set to a nominal voltage

of 14 volts AC, which gives a DC measurement of 16 volts - as shown on my

multimeter - across the power terminals with the motor running. With a

5-amp DC ammeter in the circuit, I obtain a DC current reading of 0.3 amp.

So the motor is drawing about 4.8 watts - just 8%, or about one-twelfth,

of the power used by a 60-watt light bulb.

I've done a similar measurement with the power supply turned up to its

maximum voltage setting (20 volts AC). In this case, with the motor

running, I get a reading of 24 volts DC at the power terminals and a

current of 0.4 amp; thus the motor is drawing 9.6 watts from the power

supply (just twice as much as for the above scenario). With this set-up,

the motor runs at one revolution in 10 milliseconds, i.e. at 6,000 rpm (as

opposed to 5,000) - and that's pretty scary, sounding rather like some

kind of power-tool. (Click

here

to see an mpeg movie.) I don't leave it running at that speed for any

length of time, just in case. (In fact, on occasion I've been able to get

it to spin with the wheel completing a revolution in 9 milliseconds,

corresponding to a speed of 6,666 rpm - and that is really freaky!)

Here are some links to other web-pages which are well worth a visit.

Initially, just look them over to get the gist of what they're about, then

perhaps read parts of them in more detail to get ideas for your own

researches. (But don't get too bogged down in them, because they're

basically discussion pages, and they tend to be a bit "rambling" by their

very nature.)

http://www.energeticforum.com/renewable-energy/364-bedini-sg.html

http://www.energeticforum.com/renewable-energy/366-bedini-solid-state-oscillators-2.html

http://radiant.100free.com/zpe_bedini_solid.html

http://www.energeticforum.com/renewable-energy/366-bedini-solid-state-oscillators.html#post4023

http://72.52.145.132/renewable-energy/2003-free-energy-last-step-step-must-see-15.html

http://www.overunity.com/index.php?topic=6688.msg159178

Now, some links to YouTube videos.

First, an interview with John Bedini:

http://www.youtube.com/watch?v=0PBHePZ_6U8&NR=1

Second, an animation which explains the operation of a motor which is

charging a battery:

http://www.youtube.com/watch?v=yi7cmUpMdX8&NR=1

Third, a "slide show" of several circuit diagrams for variants of the

basic monopole motor circuit:

http://www.youtube.com/watch?v=Ee9uYqFb-OI&NR=1

Fourth - I'm not sure what's going on here, but about halfway

through the video things get pretty spectacular!

http://www.youtube.com/watch?v=grQVV6hvvgo&NR=1

Fifth - this is a funny one. The guy has put something together that looks

anything but neat and tidy, but claims that he's charging a battery very

nicely. Well worth a look, and you'll get a chuckle out of it.

http://www.youtube.com/watch?v=qMB-MIiCzio

Sixth - this looks very impressive. As the video points out, nobody can

prove to anybody else that these things really work as claimed - you have

to do that for yourself. I get the distinct impression that he's made his

point very well.

http://www.youtube.com/watch?v=Zv1npBgWEbk&NR=1

Seventh - this one gives a big raspberry to the "Mythbusters" TV program

which claims to have "busted" the Bedini motor. This fellow has a sense of

humour, a bit of attitude, and a working machine: "You didn't build it

right..."; "It's not perpetual motion, it's not free energy, but it

charges batteries..." (One of the best of these videos, in my opinion.)

http://www.youtube.com/watch?v=QHfftseq908&feature=related

It's worth reading the bulletin board comments on that page. There's no

shortage of people who are delighted to pour scorn on the video and its

makers, but who (a) have never actually built a model to prove or disprove

the claims, and/or (b) are missing the point that no-one is

claiming to be creating energy - merely channeling it from one

place to another.

On the seventh page of those comments is one which appears to be from the

video's authors which I think sums the matter up very well:

All I can say is that the "secret" lies in the magnets, I guess. A small amount of energy pulls them,

but as they pass, a larger amount is discharged somehow...

Some of the video's critics decried the fact that they were using their

car battery to power the motor, and only charging small batteries,

suggesting that they could probably have achieved the same result by using

the car battery directly, without the need for the motor. A second video

addresses that criticism by having both the drive battery and the charging

battery of the same type - both small gel batteries. It's well worth a

look:

http://www.youtube.com/watch?v=xRavED3KVKc&NR=1

- and, interestingly, most of the cynics seem to have faded away!

One more from these characters - they've added a second coil with its own

circuit (as each coil needs its own), and their bicycle wheel spins

quite a lot faster as a result:

http://www.youtube.com/watch?v=kx1BOd_mnJk&NR=1

That's enough video links to be going on with - there are plenty more

which you can find within those YouTube pages, and of course you can use a

search engine to dig out even more for yourself.

Finally, a link to a web-page which discusses the "bust" mentioned above,

among other disturbing matters. Perhaps the most important of these links;

PLEASE READ:

http://www.panacea-bocaf.org/johnbedini.htm

Also, follow the links within that page - especially the one about the

Mythbusters.

SUMMARY AND CONCLUSION

In this page, and the page about my

first monopole motor,

I have simply given an account of my own first attempts to follow in the

footsteps of others who claim to have found a way to tap into zero-point

energy. I'm not making any claim to have produced an "over-unity" model of

my own. I may eventually succeed in doing so; or I may not. [Bear in mind

that John Bedini (JB), the monopole motor's inventor, has been engaged in

this research since 1984 - a quarter of a century ago.]

The important thing is that the existence of ZPE is accepted,

albeit somewhat uneasily, by the mainstream scientific community; and that

serious, sincere interest has been expressed over time by respected

scientists in the notion that it may well be possible to put ZPE to work

as a clean, safe, sustainable source of practical energy for our everyday

needs. (The names Werner Heisenberg, Arthur C. Clarke, Hal Puthoff, and of

course Nikola Tesla - among others - come to mind in this regard.)

It is time for mainstream science to embrace these ideas. It is also time

for our political and business leaders to get involved to make it happen.

With our world facing environmental disaster - as is now becoming

increasingly clear, as day follows day - we can't afford to sit on our

hands any longer.

By drawing attention to one possible means of accessing ZPE - the monopole

motor - I'm simply trying to help spark a movement of concerned citizens

to force our leaders to take the matter seriously. It's not particularly

difficult or expensive to make a model which at least illustrates the

basic principle. If enough people around the world get involved with this,

and make a point of going public about it - as I am doing via this website

- just maybe we can get the attention of those with the real power

to bring it about, sooner rather than later. The need is urgent and the

time is short.

That's my challenge. Please - get involved. Build a model yourself - or

encourage technically-minded people you know to do so, if you don't feel

up to it yourself - and spread the word. If you do succeed in

making a viable machine which taps into ZPE well enough to be

"self-sustaining", yell about it! Show it off in public; get the press,

radio, or television involved; exhibit it in a science museum if you can;

put it on your own website - anything, to help get the message out.

With a global community of people doing what they can to draw attention to

the need for properly-funded, globally-coordinated ZPE research, the

"movers and shakers" won't be able to push the matter aside for much

longer. The time to act is now.

My home page

Preliminaries (Copyright, Safety)

Mad Teddy's researches

Mad Teddy's researches

into zero-point energy

My second "monopole motor"

>>>

Nikola Tesla's 153rd birthday

<<<

To begin - a few preliminaries. The first few paragraphs in this

page are very similar to the corresponding paragraphs in my

My first monopole motor

page, because - as in that page - there are some important things that

need to be said to avoid misunderstandings, and in the interests of

safety. So, apologies for being a bore and pretty much repeating myself; I

wouldn't do so if I didn't think it was essential.

×251 + 1 = 7

×251 + 1 = 7 ×41

page, posted in January 2009 to welcome in the new year. Now, the time

has come to post a web-page addressing its subject matter in some detail.

×41

page, posted in January 2009 to welcome in the new year. Now, the time

has come to post a web-page addressing its subject matter in some detail.

)

)

I figured that with one of these, and four of

those powerful magnets, I could put together a rotor which might work

even with that crummy coil.

I figured that with one of these, and four of

those powerful magnets, I could put together a rotor which might work

even with that crummy coil.

Here you can see the box with the square piece of old wood, drilled as

described above, with its four powerful magnets - which were repelling

each other furiously!

Here you can see the box with the square piece of old wood, drilled as

described above, with its four powerful magnets - which were repelling

each other furiously!

Here's the box with the lid safely in place. (That was quite a relief!)

Here's the box with the lid safely in place. (That was quite a relief!)

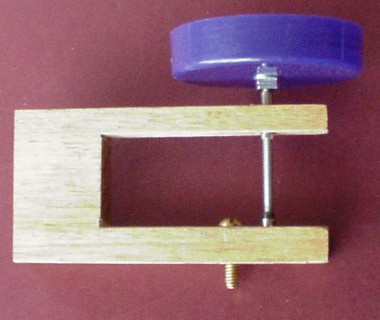

To mount the rotor, I cut a piece of 19mm timber and carefully drilled a

hole through its entire width, only then cutting out a piece to

accommodate the rotor. This was to make absolutely sure that the top and

bottom holes would line up accurately.

To mount the rotor, I cut a piece of 19mm timber and carefully drilled a

hole through its entire width, only then cutting out a piece to

accommodate the rotor. This was to make absolutely sure that the top and

bottom holes would line up accurately.

Showing the disc next to the recess...

...and in situ

There was an audible oscillation (as there had been when running my

first monopole motor from a gel battery). I gave the rotor a spin.

To my huge delight, it kept spinning - and speeded up quite dramatically!

Click

here

to see a 15-second, 1.3Mb mpeg movie.

There was an audible oscillation (as there had been when running my

first monopole motor from a gel battery). I gave the rotor a spin.

To my huge delight, it kept spinning - and speeded up quite dramatically!

Click

here

to see a 15-second, 1.3Mb mpeg movie.

At some stage during the day's proceedings, I put the red and orange

stickers onto the rotor, and took more movies showing the rotor both

speeding up and slowing down. Click

here

and

here

to see them.

At some stage during the day's proceedings, I put the red and orange

stickers onto the rotor, and took more movies showing the rotor both

speeding up and slowing down. Click

here

and

here

to see them.

)

)

Click on the picture to see the original full-size photograph

(Reconstruction - another magnet placed there later and photographed)

As you can see, that strip metal and an NdFeB magnet are blithely ignoring

each other.

As you can see, that strip metal and an NdFeB magnet are blithely ignoring

each other.

It was now Friday, 21st November 2008. I decided that, before installing

the new rotor, it would be interesting to have one last try with the

skateboard wheel. Click

here

to see the result (1.3Mb, 15 sec).

It was now Friday, 21st November 2008. I decided that, before installing

the new rotor, it would be interesting to have one last try with the

skateboard wheel. Click

here

to see the result (1.3Mb, 15 sec).

It's perhaps worth mentioning that those dome nuts (right) are not the

same as the one used for the lower end of the axle.

It's perhaps worth mentioning that those dome nuts (right) are not the

same as the one used for the lower end of the axle.

This photo is one frame from an mpeg movie showing the motor being

switched on and then started spinning by hand. The neon light can be seen

glowing with neon's characteristic orange glow, flickering slowly at first

and then faster as the motor speeds up.

This photo is one frame from an mpeg movie showing the motor being

switched on and then started spinning by hand. The neon light can be seen

glowing with neon's characteristic orange glow, flickering slowly at first

and then faster as the motor speeds up.

The muffled music at the start is coming from my son's

computer in the room above - he was "YouTube-ing".

Some time before, I'd done a very silly thing and purchased a second-hand

12V gel battery from "you-know-where" and found, to my very unreasonable

annoyance, that it was as flat as the proverbial pancake. (Granted, it

only cost me two lousy bucks - but it was the principle of the

thing that galled me.)

Some time before, I'd done a very silly thing and purchased a second-hand

12V gel battery from "you-know-where" and found, to my very unreasonable

annoyance, that it was as flat as the proverbial pancake. (Granted, it

only cost me two lousy bucks - but it was the principle of the

thing that galled me.)

I made a point of doing the experiment outside, just in case it was

too successful - with the battery perhaps exploding.

I made a point of doing the experiment outside, just in case it was

too successful - with the battery perhaps exploding.

(BTW - that wheelie-bin is the subject of one of my poems; click

here

to read it.)

Nothing to get too excited about, really! I suspect that the battery was

simply too far gone to be rescued. (Since then, it's dropped back down to

about 0.43 volts.)

As already mentioned, the motor oscillates, or "sings", when it's first

switched on. I hooked up an oscilloscope probe across the drive coil and

took some pictures of the waveform; this is the best one I could get.

As already mentioned, the motor oscillates, or "sings", when it's first

switched on. I hooked up an oscilloscope probe across the drive coil and

took some pictures of the waveform; this is the best one I could get.

=> n/12 = ln3.636363.../ln2 = 1.3625 (approx)

=> n = 22.35

Click

here

to see an mpeg movie (1.3Mb, 15 sec.) of the waveform generated by giving

the rotor an initial spin from an initial "high-G" standing start. (The photo at left is one

frame from that movie.)

Click

here

to see an mpeg movie (1.3Mb, 15 sec.) of the waveform generated by giving

the rotor an initial spin from an initial "high-G" standing start. (The photo at left is one

frame from that movie.)

With the rotor at maximum speed, there's only time for two "spikes" per

quarter-revolution. You can see how the waveform has assumed the familiar

shape - other than the fact that there's not just one spike, but two, each

time.

With the rotor at maximum speed, there's only time for two "spikes" per

quarter-revolution. You can see how the waveform has assumed the familiar

shape - other than the fact that there's not just one spike, but two, each

time.

As I've mentioned elsewhere, many claimed ZPE devices combine the dual

attributes of permanent magnets and high-voltage transients. This is

definitely the case with Bedini monopole motors. So it's my strong sense

that the author of that comment has absolutely hit the nail on the head

there. (Again, may I remind you of Heisenberg's assertion that we could

utilize magnets as an energy source.)

MAD TEDDY

MAD TEDDY

Celebrating life

on the spectrum

and trying to help save the world -

with

junk

Return to my ZPE researches menu page

Return to my ZPE researches menu page